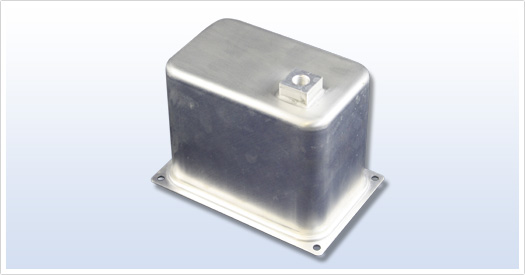

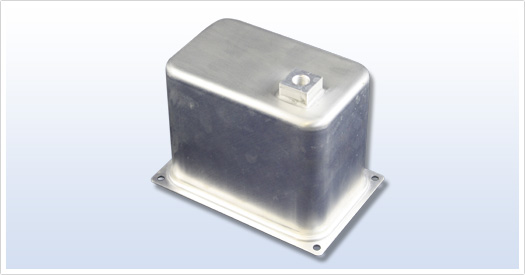

Dip Brazed and Deep Drawn Medical Battery Housing

Dip Brazed and Deep Drawn Medical Battery Housing

This aluminum battery housing was manufactured using CNC machining. This medical part was dip brazed and has a clear anodized coating.

Dip Brazed and Deep Drawn Medical Battery Housing

Dip Brazed and Deep Drawn Medical Battery Housing

This aluminum battery housing was manufactured using CNC machining. This medical part was dip brazed and has a clear anodized coating.

Deep Drawn Aluminum Battery Housing

Deep Drawn Aluminum Battery Housing

This is a deep drawn aluminum battery housing for use in medical applications. The surface has been treated with a brazing agent. Its dimensions are 16″ x 12″ x 12″.

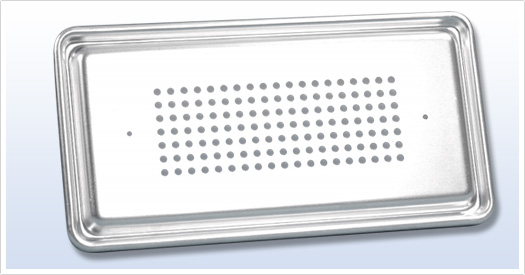

Deep Drawn Aluminum Medical Case Cover

Deep Drawn Aluminum Medical Case Cover

This is a deep drawn aluminum case cover made for medical applications. It has been pierced and includes a drawn bead, polished, anodized finish. Its dimensions are 8″ x 12″ x 1″.

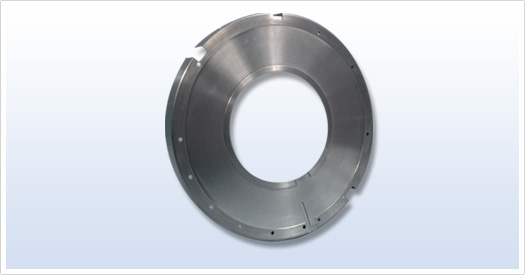

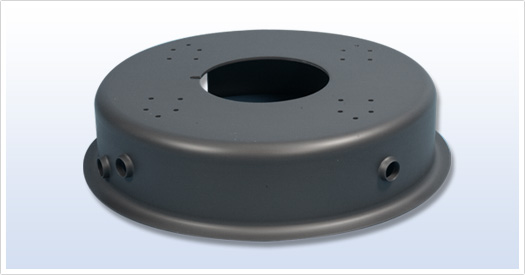

Deep Drawn Aluminum Rotor

Deep Drawn Aluminum Rotor

This is a deep drawn aluminum rotor for use in medical applications. It has been flame blazed, machined, and painted black. Its dimensions are 6″ x 4″ x 4″.

Hydroformed Stainless Steel Cover

Hydroformed Stainless Steel Cover

This is a hydroformed stainless steel cover manufactured by Amalco for use in medical applications. Secondary operations included sharpening the edges. Its dimensions 1″ x .5″.

Hydroformed Aluminum Cap Pierced

Hydroformed Aluminum Cap Pierced

This is a hydroformed aluminum cap that has been pierced for use in medical applications. Its dimensions are 2″ x 1″.

Hydroformed Aluminum Blood Analyzer Component

Hydroformed Aluminum Blood Analyzer Component

This is a hydroformed aluminum blood analyzer component made by Amalco for use in medical applications. It has been CNC machined, punched, and notched. Its dimensions are 24″ x 1″.

Hydroformed Aluminum Cover

Hydroformed Aluminum Cover

This hydroformed aluminum cover was made by Amalco for use in medical applications. Its dimensions are 3″ by ½”.

Deep Drawn Blood Analyzer Liner

Deep Drawn Blood Analyzer Liner

This is a blood analyzer liner deep drawn for a medical instruments manufacturer. Multiple draws were combined with piercing and hard coat anodizing to form this 24″ x6″ aluminum medical device.

Deep Drawn Medical Sterilization Tray

Deep Drawn Medical Sterilization Tray

This is a deep drawn sterilization box pressed for a medical manufacturer. It was formed in a single deep draw operation from aluminum and has dimensions of 8″ x 12″ x 4″.