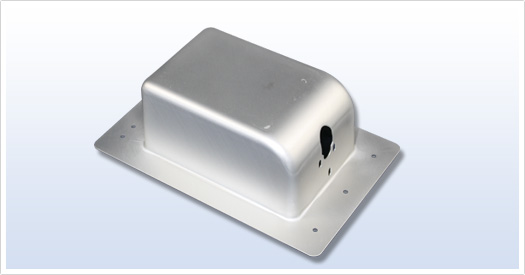

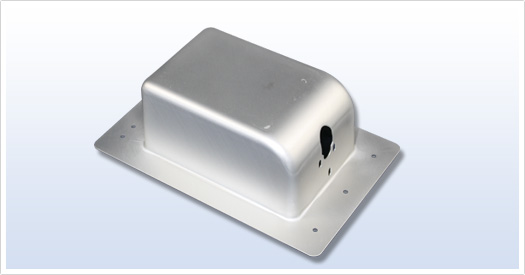

Deep Drawn and Hydroformed Aluminum Electrical Cover

Deep Drawn and Hydroformed Aluminum Electrical Cover

This is an aluminum electrical cover hydroformed and deep drawn for use in industrial applications. The holes have been CNC machined with an RoHS-compliant iridite finish. RoHS means that it adheres to Restriction of Hazardous Substances regulations. The dimensions of this piece are 5″ x 10″ x 4″.

Rolled Steel Gage Cover

Rolled Steel Gage Cover

This is a rolled steel gage cover made by Amalco for industrial use. It has been welded, formed, and notched. Its dimensions are 8″ x 24″.

Deep Drawn, Hydroformed and Dip Brazed Aluminum Starter Housing

Deep Drawn, Hydroformed and Dip Brazed Aluminum Starter Housing

This aluminum starter housing was manufactured from sheet metal using CNC machining and a combination of hydroforming and deep drawing processes. Its been spot welded and dip brazed, and its dimensions are 8″ x 10″ x 4″.

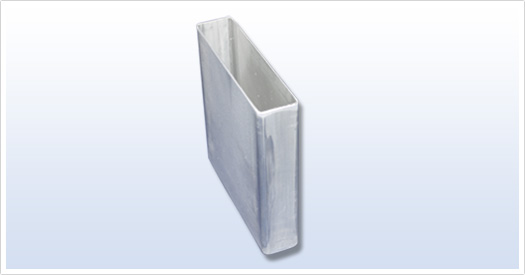

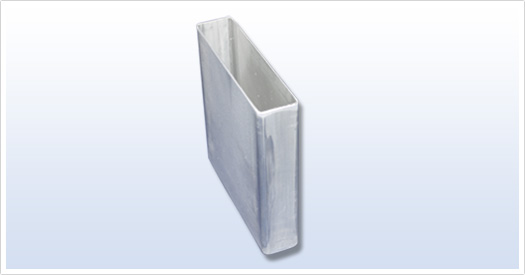

Deep Drawn Aluminum Battery Housing

Deep Drawn Aluminum Battery Housing

This deep drawn aluminum battery housing was manufactured by Amalco using a multiple draw process. Secondary operations included sharpening to obtain finely honed corners. Its dimensions are 2″ x 6″ x 8″.

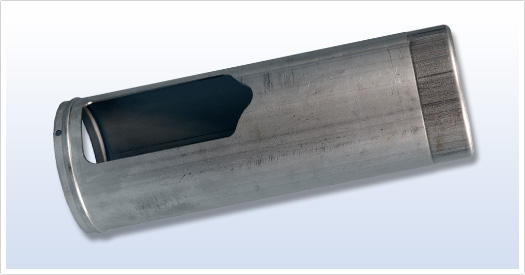

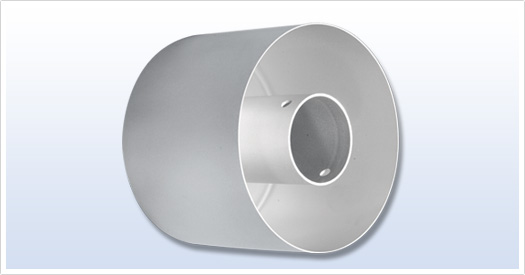

Deep Drawn and Dip Brazed Aluminum Hydraulic Chamber

Deep Drawn and Dip Brazed Aluminum Hydraulic Chamber

This is a deep drawn aluminum hydraulic chamber, manufactured by Amalco with CNC machining. This part has been machined to ± .003 on all dimensions prior to dip brazing. Secondary operations include anodizing and x-raying. Its dimensions are 10″ x 16″.

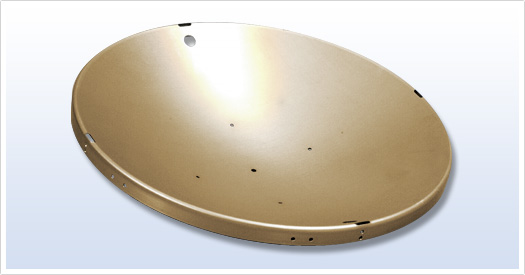

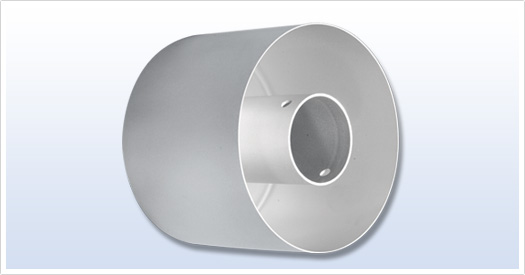

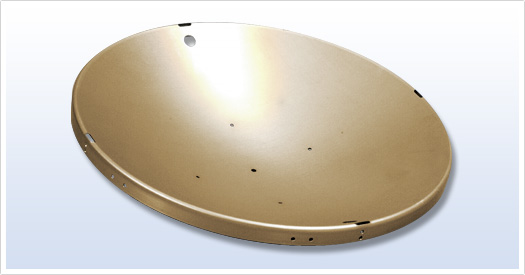

Deep Drawn Aluminum Satellite Dish

Deep Drawn Aluminum Satellite Dish

This is a deep drawn aluminum satellite dish for use in industrial applications. Its surface has been finished with a chemical iridite coating. Its dimensions are 24″ x 8″.

Deep Drawn Aluminum Battery Housing

Deep Drawn Aluminum Battery Housing

This is a deep drawn aluminum battery housing for use in medical applications. The surface has been treated with a brazing agent. Its dimensions are 16″ x 12″ x 12″.

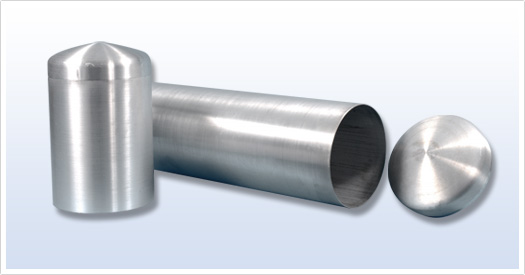

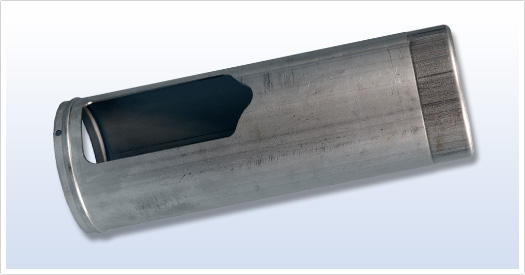

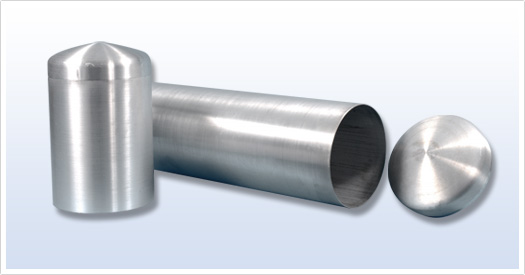

Deep Drawn Aluminum Time Capsule with Emery Finishing

Deep Drawn Aluminum Time Capsule with Emery Finishing

These are deep drawn aluminum time capsules made by Amalco for industrial use. These time capsules are welded and include fitted caps and an emery finish. The time capsules shown here are 12″ wide. Lengths range from 1-4 feet.

Deep Drawn Aluminum Float

Deep Drawn Aluminum Float

This is a deep drawn aluminum float made by Amalco using a reverse draw process. Its dimensions are 8″ x 8″.

Deep Drawn Aluminum Snare Drum

Deep Drawn Aluminum Snare Drum

This is a deep drawn, spun aluminum snare drum. It has been pierced and finished with a powder coating. The snare drum shown here is 24″ in diameter and 10″ tall.

Deep Drawn and Hydroformed Aluminum Electrical Cover

Deep Drawn and Hydroformed Aluminum Electrical Cover