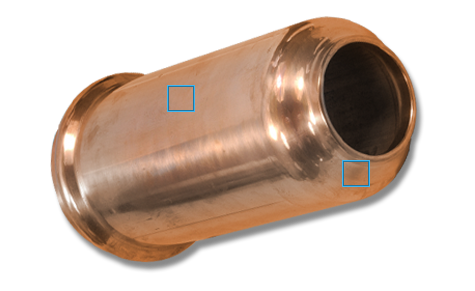

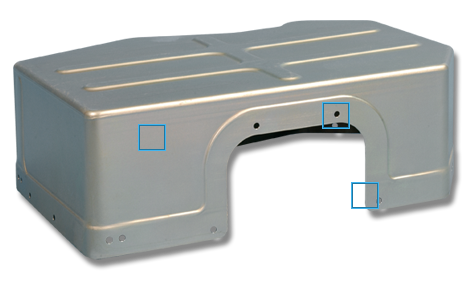

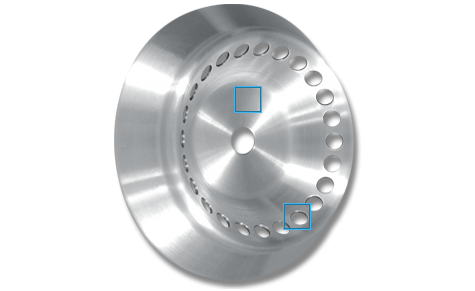

QUALITY SYSTEM (CONFORMS TO MIL-I-45208)

We maintain a MIL-Grade Quality System, which enabled us our commercial customers to benefit from the same critical standards that have allow to supply defense contracting components to the US government and Military. At Amalco, we employ the latest technologies and QC inspection processes, and we maintain our own QC Manual focused on the goal of attaining “Zero Defects on All Products Produced.”