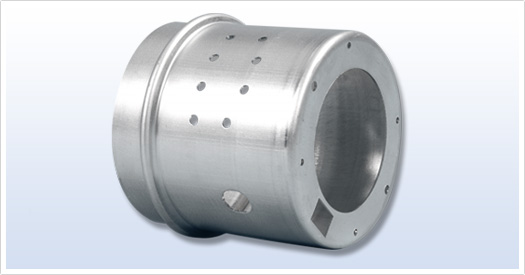

Deep Drawn Aluminum Light Housing

Deep Drawn Aluminum Light Housing

This is a deep drawn aluminum light housing made by Amalco. It has been pierced and includes a rolled bead finishing. The dimensions of the unit shown here are 8″ x 9″.